More accurate measurements reservoir monitoring are in the pipeline

The SHAPE project will improve data processing and uncertainties characterisation. This will shed light on important aspects of CO2 injection and storage.

SHAPE project

Surface uplift is measured with millimeter precision by surveying or satellite monitoring (InSAR, GPS). When the surface rises, there is room for more CO2. In the Algerian Sahara, surface uplift around CO2 injection wells has been linked to stress changes in the rocks above the reservoir. At sea, measurements of water pressure on the seabed can provide similarly high precision. SHAPE is the acronym for this technology. The SHAPE project focuses on dynamic storage capacity, distribution of CO2 in the reservoir, unwanted fracturing, and injection outside the desired zone. More results will be available in autumn 2024. Stay tuned!

Better equipped

Factors such as station stability, network design, sensor behavior, tides and other oceanographic variations affect accuracy. By analyzing a large data set from the Troll field. Some corrections have been improved and some sources of error have been isolated. The pressure drops and compaction of the rock as a result of gas production is the opposite of what is expected with CO2 injection. But the measurement method is the same. Probably also the elastic properties of the reservoir rock. Different uncertainties described make it easier to predict detection limits when planning monitoring projects.

Troll&Aurora

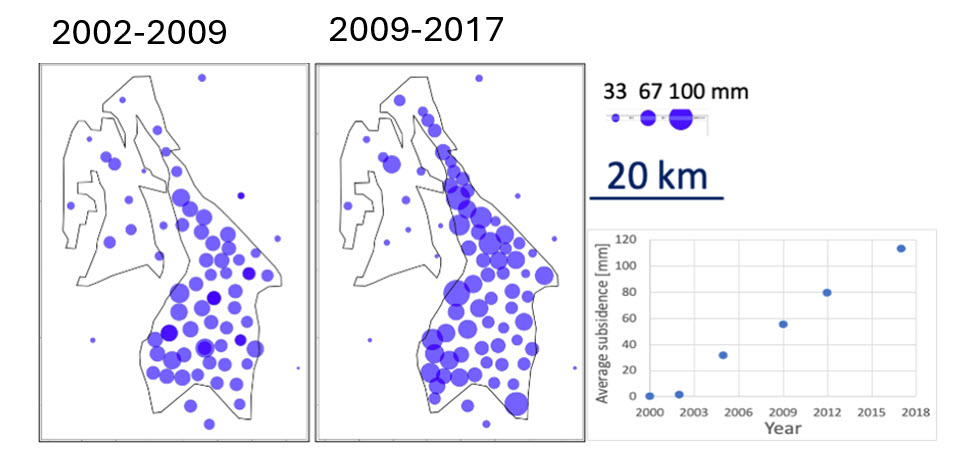

The project has analyzed data from about 100 stations over the Troll field in the period 2000 to 2017. The seabed in this area has been sinking at an average rate of almost one centimeter per year. During this period. The North Sea has received about four million cubic meters more seawater because of gas production at Troll.

The errors within each series of measurements have a standard deviation of 2-3 millimeters. Some of the measurement foundations have moved in relation to the ground. The fact that the reference level for depth is floating (sea level) adds to the uncertainty.

Based on the subsidence data and the pressure drop measured in the wells. The project can estimate the pressure drop in the water-filled formations below and to the side of the gas reservoir. In addition, the properties measured in the Cook and Johansen formations in well 31/5-7 southwest of Troll (Northern Lights’ Aurora CO2 storage site) are used to estimate that the seabed above Aurora can rise by 10 centimeters or more even at moderate injection pressures.

Implications for future CCS projects

Such monitoring may be valuable for future CO2 injection. A resolution in the conversion of uplift to reservoir pressure of perhaps 1-2 bar can be valuable in verifying flow models. For example, it can help to locate pressure barriers in relation to an injection well and thus be used to control the injection rate.

Mature enough to monitor CO2 injection

– The project would never have got off the ground without the support from the CLIMIT programme. The measurement technology would have existed, but without these improvements it would not have been targeted at CO2 injection and storage,” says Ola Eiken at Quad Geometrics.

He goes on to say that the technology for measuring seabed uplift is now mature enough to monitor CO2 injection. “A remaining bottleneck is practical experience and analysis tools (software) to link observations and modelling of pressure changes in the reservoir.”

Pilot testing important for cost-effective CO₂ capture

Many products in today’s market are manufactured through industrial processes. That release substantial amounts of CO2. Hence it is imperative for the industry to find cost-effective solutions to avoid CO2 being released into the atmosphere.

Pilot plants serve as small-scale process facilities where technology providers and industry can collaboratively test and demonstrate CO2 capture technologies. This occurs under realistic conditions, often preceding decisions on full-scale implementation.

Avoiding costly mistakes

– A pilot plant provides the opportunity to refine the technology. Challenges can be identified and addressed on a smaller scale.Minimizing the risk of expensive errors during implementing. And operation in full-scale facilities. It also allows for improvements and innovations enhancing the technology’s long-term cost-effectiveness, says Svein Bekken, Senior Adviser at Gassnova.

A pilot plant also provides valuable knowledge through learning. Benefitting both technology providers and technology users (the industry). Understanding how the technology reacts under real conditions. Considering emissions, temperatures, and other operational factors. Enables providers and customers to evaluate and optimise the capture system’s performance. Ensuring its robustness for full-scale implementation in any industrial scenario.

Cost-efficient and sustainable technology

To achieve climate change targets. CO2 capture technology is a key component for much of the energy intensive industries. Both nationally and internationally. Testing their technology under real industrial conditions is essential for providers. As it is impossible to simulate or predict all the challenges in an industrial context.

– At the same time. It is crucial for industrial companies (CO2 emitters) to gain knowledge about the capture technology they might implement in their own plants. This includes knowledge of what is required in terms of preparation. And changes to the infrastructure in and around their own facilities, says Jørild Svalestuen, Senior Adviser at Gassnova.

The Lesson Learned report from Longship shows that 34 percent of the costs of CO2 capture are related to infrastructure (“Utility and Support Systems”). Early phase of pilot testing is very useful for both technology providers and technology users (CO2 emitters), especially for industries where CO2 capture has not been tested previously.

Interaction with the industry

CLIMIT has supported pilot tests at facilities such as: SINTEF’s CO2 capture pilot test centre at Tiller, Trondheim, the Technology Centre Mongstad (TCM) and mobile test units owned by various technology providers. Below are examples of companies that have tested their technology with support from industry and CLIMIT:

- Aker Carbon Capture has at the request from industry, demonstrated its own capture technology in different type of industries using a mobile test unit. These include companies such as Heidelberg Materials in Brevik, Hafslund Oslo Celsio in Oslo, Preem AB in Sweden, Polchar in Poland, Elkem and SMA Mineral in Mo Industripark. In earlier phases, the solvent technology was tested and optimised in collaboration with NTNU and SINTEF. The technology was further tested, developed, and qualified at TCM for further use at larger scale.

- Hydrogen Mem-Tech’s technology for separating hydrogen from CO2 has been tested under real conditions at Equinor’s plant in Tjeldbergodden.

- Baker Hughes’ Compact Carbon Capture technology, developed in Norway in collaboration between Fjell Technology Group, Equinor and SINTEF – with support from CLIMIT. The technology has been tested at Equinor’s pilot plant in Porsgrunn.

- Fjell Technology Group’s Moving Bed Carbonate Looping technology, developed in collaboration with NTNU and SINTEF, is scheduled for pilot testing – with a mobile unit under construction for testing in industrial environment.

- Air Products in Kristiansand has tested two types of membranes for CO2 capture at Heidelberg Materials in Brevik. They are currently being testing their commercial membrane at Returkraft in Kristiansand.

- SINTEF’s patented CSAR (Continuous Swing Absorption Reactor) CO2 capture technology will be tested at Bergen Area Inter-Municipal Waste Disposal Company (BIR).

The CLIMIT programme has been making a difference for almost 20 years. Supporting the development of CO2 capture technologies and conducting pilot-scale testing in industrial conditions. Has been significant for technology providers and the industry that will adopt this technology.

CETP; Norwegian partners dominate in the EU

CLIMIT support paves the way for Norwegian project collaboration on CO2 management in Europe.

The Clean Energy Transition Partnership (CETP) is an EU initiative that brings together public and private stakeholders in research and innovation ecosystems. CETP’s goal is to foster innovation across borders and contribute to the EU’s objective of becoming the first climate-neutral continent by 2050.

The path to this goal involves a wide range of technologies and system solutions, which can receive financial support from the granting bodies in CETP participant countries.

Projects with international perspective

Today, CLIMIT R&D allocates a significant portion of its budget to international collaboration through CETP. As a result, CLIMIT’s advice to potential applicants is to have an international perspective on their projects, including forming partnerships with attractive foreign entities.

One of the CETP areas includes CCS/CCU, where 10 new projects are in the startup phase. In addition six of them with Norwegian partners, and five of these receive support from CLIMIT. Norwegian applicants must meet the requirements outlined in CLIMIT’s program plan to succeed, which also involves supporting the Longship’s benefits realization.

If the Norwegian part of an application can be supported by CLIMIT, but foreign partners are denied on their side. The application may be rejected. The project must meet the requirements for support from the respective country’s granting body. There are examples where the Norwegian part of an application has put in a lot of effort, only for the foreign entity to be denied on their end. Consequently, the feasibility of the project must be checked against the respective countries’ program plans and priorities, early in the planning process.

When granted, these funds collectively provide significant momentum to project implementation, along with knowledge and innovation shared across borders. An important part of CLIMIT’s mandate.

CETP`s first call in 2022

There was a sub-call titled “Enabling Climate Neutrality with Storage Technologies, Renewable Fuels, and CCU/CCS.” The projects that received grants were decided in June 2023. Afterward formal agreements were reached bilaterally, before the start of individual projects from November 2023, and beyond:

|

Project |

Coordinator |

Topic |

|

ACLOUD |

Tobias Mattisson, Chalmers (Sweden) |

CO2 capture |

|

AMbCS |

Saravanan Janakiram, Aqualung (Norway) |

CO2 capture |

|

BUCK$$$ |

Kun Tian, Universita Roma La Sapienza (Italy) |

CO2 mineralization |

|

CO2RR |

Laura Camarut, South Pole (Switzerland) |

CO2 value chain |

|

CTS |

Roman Berenblyum, NORCE (Norway) |

CO2 storage |

|

DRIVE |

Peter van Os, TNO (The Netherlands) |

CO2 capture |

|

GreenSmith |

Eric van Dijk, TNO (The Netherlands) |

CO2 capture |

|

LEGACY |

Bastien Dupuy, SINTEF (Norway) |

CO2 storage |

Details about the projects can be found on CETP’s website.

Call for proposals in 2023

The second CETP proposal received project outlines in November. The most promising ones are requested to submit a complete application in March. CETP’s approval decisions will be made in June 2024.