How CCS works

“Capturing carbon dioxide is not new technology – it has been carried out in the chemical industry since the 1940s.”

Remove CO2

CCS is a group of complementary technologies which remove carbon dioxide from fossil-fuel power plants and large-scale sources, such as energy-intensive industries (for example steel, cement and refining.) CCS can also be used on bio-based industries (called bio-CCS or BECCS) as a CO2 negative emissions technology, whereby it actually removes carbon dioxide from the atmosphere.

Additionally, capturing and storing the CO2 from the process in which pure hydrogen is extracted from natural gas results in a source of low-carbon hydrogen. This can be used to remove emissions from several areas such as domestic and industrial heating, heavy onshore transportation and in the maritime sector.

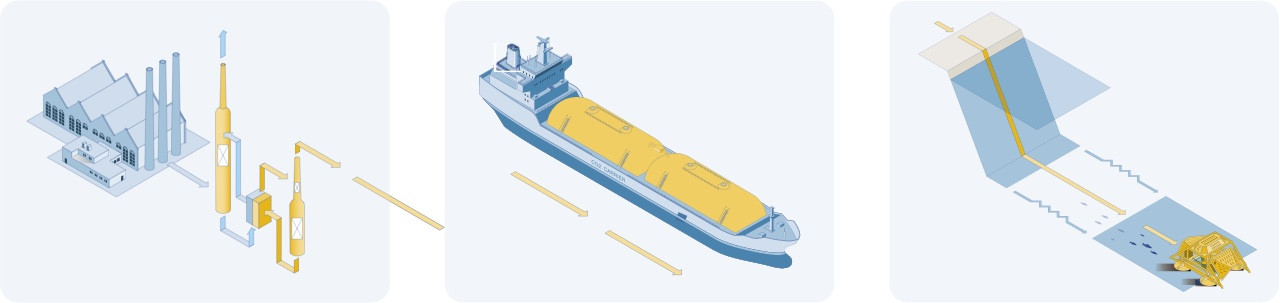

First: Capture

The first stage in the CCS process is the capture of CO2 from the gases emitted during the burning of fossil fuels or biomass, as well as capturing CO2 from industrial processes such as steel-making, cement, chemicals and refining.

There are several different technologies for CO2 capture at different maturity levels. In some cases, CO2 can be an integrated part of the production process.

The cost of CO2 capture varies from source to source depending on several factors. For example, the proportion of CO2 that is entrained in the exhaust gas, the availability of low-cost energy/heat, and opportunities to integrate CO2 capture in the production process. This means that some facilities are low-hanging fruit for implementing CCS.

Second: Transport

Once captured, carbon dioxide is transported by pipeline or ship to a suitable storage site. The technologies involved in transportation are similar as those used extensively for transporting food grade CO2 and natural gas around the world.

Transportation of carbon dioxide has been carried out for over 40 years (particularly in the US for use in Enhanced Oil Recovery). Transportation of CO2 by ships and road is part of the daily business in the food grade CO2 market but in smaller volumes.

There are currently 7,762 km of operational carbon dioxide pipelines in the United States.

Third: Store

CO2 can be isolated from the atmosphere by a variety of techniques. Currently, the most cost-effective technique for safely storing large volumes is to mimic nature and recycle the carbon back into the Earth’s sedimentary basins – from where humans have extracted it in the form of fossil fuels. This process is referred to as geological storage of CO2, or just CO2 storage.

Once carbon dioxide has been transported to a suitable location in liquid form, it is pumped into an oil or gas reservoir, which may or may not hold natural reserves of hydrocarbons or CO2 from before. The common feature of any suitable reservoir rock is that it contains a fine network of small, interconnected pores that allow the liquid CO2 to mingle with salt water already present underground.

These fluids remain a great distance below the surface and are separated from it by multiple layers of the kinds of impermeable, clay-rich rock which make finding oil and gas deposits so challenging.

Industrial experience of injecting CO2 underground is widespread, ranging from Canada and the US to Brazil, Turkey, China and Hungary.