- How did we get here?

- Gassnova establised 2005

- Work on CO2 management is stepped up

- Gassnova plays an important role in CO2 management

- Mongstad full-scale postponed

- Success for the Technology Centre and CLIMIT

- Too much uncertainty

- Idea study reveals industrial interest for CO2 capture

- Full-scale feasibility studies completed

- Work on full-scale put on hold

- Resuming the work on fullscale CCS

- Changes for CLIMIT

- The technology centre has found its place in the value chain

- Longship announcement adopted September 2020

The Gassnova story

Gassnova is currently based at Powerhouse Telemark in Porsgrunn. The organisation manages the state’s interests in CO2 management and shares knowledge in the field both nationally and internationally.

Gassnova’s main objective is to promote technology development and competence building for cost-effective and future-oriented solutions for CO2 management. The state-owned enterprise manages the demonstration part of the CLIMIT programme together with the Research Council of Norway’s R&D part. Is the government’s representative in Technology Centre Mongstad (TCM), where Gassnova manages the government’s 34% share. And follows the Longship project.

How did we get here?

The history of the state-owned company Gassnova stems from a political desire to increase domestic use of gas while balancing this with Norway’s energy situation, environmental considerations and value creation.

The controversy surrounding construction of gas power plants is one of the mostly hotly debated environmental issues in Norway. In 1995 the debate exploded when Naturkraft applied for a licence to build three gas power plants. In the spring of 2000, Kjell Magne Bondevik’s first government resigned after having refused to accept the Storting’s (parliament’s) desire to develop gas power without addressing CO2. When the Labour Power took control of the Government. Licences were issued for three gas power plants of which just one – the gas power plant at Kårstø – was subsequently built.

In 2001, an expert panel appointed by the Government was tasked with studying how research and development could be used to stimulate new, environmentally-friendly gas application in Norway. The panel’s mandate also included assessing various organisational forms. Designed to promote more environmentally-friendly use of natural gas for energy, “including establishing a company to promote development of environmentally-friendly technology”.

The second Bondevik government. Which took office in the autumn of 2001. Continued and reinforced this work. “The commitment to gas power with carbon capture and storage is a main element of the Government’s energy policy”. Was a stated agenda. In a Storting White Paper from 2002 on domestic use of natural gas. A key element was the establishment of a public innovation enterprise to promote environmentally-friendly gas power technologies. The Storting supported the proposal.

The Storting established the “Gas Technology Fund” in the summer of 2004. Returns from this fund were meant to finance research and development of environmentally-friendly gas power technologies.

Gassnova establised 2005

Gassnova opened its doors on 1 January 2005, as an administrative agency under the Ministry of Energy (ME). Together with the Research Council of Norway, Gassnova was to manage a research programme – CLIMIT. Using resources from the Gas Technology Fund and annual fiscal budget appropriations. The CLIMIT programme was approved as a subsidy scheme under the EEA regulations one year later. And the first development projects received funding in the summer of 2006.

Work on CO2 management is stepped up

Following the 2005 election, the Labour Party, Socialist Left Party and the Centre Party formed a majority coalition government. The 2005 political platform, the so-called “Soria Moria declaration”. Stated, among other things, that “the Government will ensure that the work to establish a full-scale CO2 removal facility at Kårstø is started. And will provide financial contributions toward this goal”. Another objective of the government was to establish a value chain for transport and injection of CO2 for geological storage.

In the late autumn of 2005, Gassnova was assigned the task of facilitating broad-based cooperation on carbon caption and storage, CCS/CO2 management. Three projects were initiated, and Gassnova’s initial role was to cooperate with Gassco and the Norwegian Petroleum Directorate. An important issue was to attempt to identify profitable applications for captured CO2 for enhanced oil recovery (EOR). A task also attempted, without success, by several oil companies.

Statoil received an emission permit for a new combined heat and power plant at Mongstad in October 2006. The Soria Moria declaration confirmed that new gas power licences would be based on removal of CO2. An agreement between the State and Statoil governed the collaboration on CO2 management at Mongstad. “Storting Prop. No. 49 (2006-2007) Cooperation on CO2 capture and storage at Mongstad” was the Government’s proposal to establish a state-owned enterprise reporting to the Ministry of Energy for the purpose of managing the State’s interests in CCS projects. Gassnova SF, a state-owned enterprise, was established on 29 June 2007 and shortly thereafter appointed the head of the administrative agency, Bjørn-Erik Haugan, as CEO. The rest of the administrative agency’s organisation was transferred to the new enterprise at the beginning of 2008.

Gassnova plays an important role in CO2 management

Gassnova was to manage the State’s interests in the work on the CCS test centre at Mongstad. Work on full-scale CO2 capture at Kårstø. As well as transport and storage of CO2.

Planning of the test centre took place from June 2007 in a collaborative effort between Gassnova and five industrial companies. Of which Statoil was the executive project manager. A proposition on establishing the Technology Centre Mongstad (TCM) was submitted to the Storting in January 2009. The TCM partners passed an investment resolution in June 2009. Following approval by the Government and the Storting.

In the spring of 2009, the Government decided to halt the procurement process for awarding contracts for a CO2 capture facility at Kårstø. Citing long downtime periods at the power plant. Gassnova and Gassco then carried out a study of potential integration of the power plant with the gas terminal at Kårstø. This report was submitted to the ME in the spring of 2010.

Mongstad full-scale postponed

The State and Statoil agreed on the work on the full-scale project at Mongstad in 2006. The development started with Statoil’s delivery in early 2009 of a master plan for CCS at Mongstad. This was followed by the institution of cooperation between Gassnova and Statoil on further planning of the facility. With the agreed ambition to make an investment decision in 2012. This work encountered unforeseen obstacles. It became evident in the spring of 2010 that the planned schedule was too rigorous. And the investment decision goal was initially postponed from 2012 to 2014.

But this was not the end of the challenges. As a consequence of the uncertainty surrounding the health-related consequences of using amine technology. The need for more knowledge surrounding this topic, yet another postponement was needed. A Storting White Paper on full-scale CCS from 2011 brought a new road map for CCS. The planned decision timeframe was set at 2016. The Government also advocated initiating a separate study on potential full-scale projects in Norway “beyond Mongstad”.

Success for the Technology Centre and CLIMIT

The world’s largest and most flexible test centre for CO2 capture technologies was constructed at Mongstad from 2009-2012. The partners were Gassnova (on behalf of the Norwegian State), Statoil (now Equinor) and Shell. South African Sasol joined in 2010. The technology centre was ready to go in May 2012. And its opening was celebrated by the entire global CO2 management community. This milestone was considered to be particularly important in order to achieve progress in the development of the climate technology essential to all nations. If there was to be any hope of achieving the climate targets.

The CLIMIT research programme receives a steadily growing number of applications. From good projects seeking support for research, development and demonstration of CO2 management technologies. The programme made its largest-ever single award in 2013. When Heidelberg Materials was granted NOK 70 million to build a unique test facility for CO2 capture from the cement industry. Where several technology suppliers could test their capture technologies simultaneously.

Too much uncertainty

In September 2013, the Stoltenberg Government discontinued the work on planning the full-scale project at Mongstad. And the associated plans for transport and storage. The Government regarded the fate of the Mongstad refinery as being so uncertain, and the risk associated with the project so great, that continuing the work would not be prudent. Gassnova had already been working for quite some time to investigate the feasibility of full-scale CCS in Norway, in locations other than Mongstad.

After eight years of a majority government made up of the Labour Party, Socialist Left Party and the Centre Party, the non-socialist parties won the 2013 election. The Conservative Party and the Progress Party formed a minority government and entered into a cooperation agreement with the Liberal Party and the Christian Democratic Party to secure a parliamentary majority. The Government maintained its ambition to realise at least one full-scale CO2 capture facility by 2020. However, they recognise that the work on CO2 management has been difficult, and they will draw up a new strategy for CCS in Norway.

Idea study reveals industrial interest for CO2 capture

The government’s new strategy for CCS/CO2 management, which was presented in the Fall of 2014 (ED’s Prop. 1 S (2014-2015)), aimed at identifying measures that could contribute to technology development and cost reductions. Which included the government’s ambition to have at least one full-scale facility in place for the capture and storage of CO2 by 2020. Gassnova continued to study the possibilities for this.

In the spring of 2015, Gassnova handed over the study of possible full-scale CCS projects in Norway to the Norwegian Ministry of Energy. The idea study showed that several industrial players could be willing to study CCS further. The industrial players’ interest in participating in a CCS project depended on the framework conditions established by the state.

In 2015, CLIMIT marked its 10th anniversary. The research programme, led by Gassnova in collaboration with the Norwegian Research Council, has over the years invested considerable funds in research and development to promote technology and solutions for CCS. The technology is ready for use, but can still be improved.

Full-scale feasibility studies completed

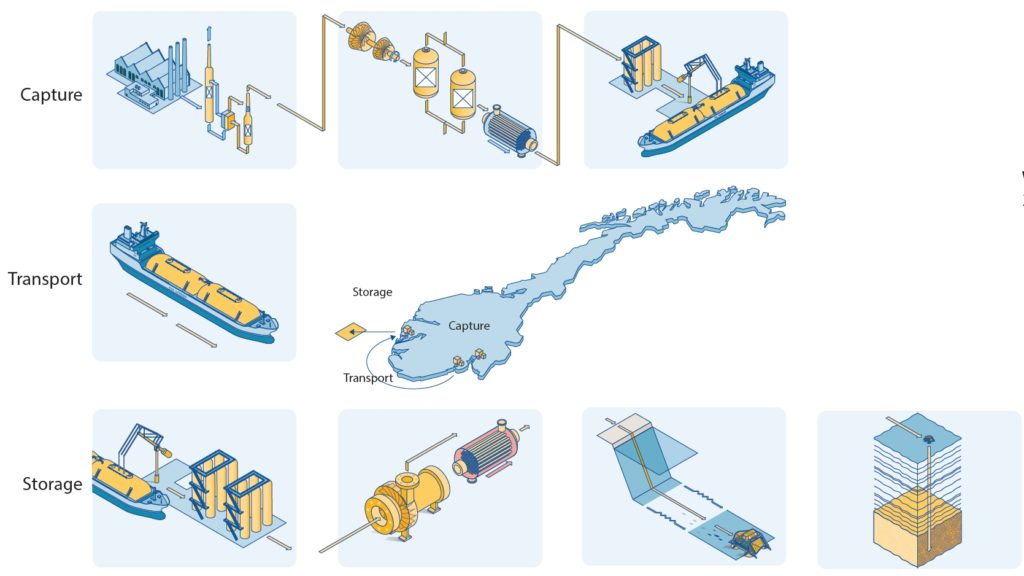

On 30 October, full-scale CCS feasibility studies were initiated with the relevant companies. The purpose of the feasibility studies was to show at least one technically feasible full-scale CCS chain with associated cost estimates. Such a chain involves the capture, transport and storage of CO2.

In the summer of 2017, the Ministry of Energy presented the feasibility study which showed that it was possible to realize a full-scale CCS chain in Norway by 2022 and at significantly lower costs than for projects previously looked into in Norway. The results also showed several alternatives that are technically feasible in Norway; Heidelberg Materials’s cement plant in Brevik, the Yara ammonia factory in Porsgrunn and the Waste-to-Energy plant at Klemetsrud in Oslo.

Statoil (now Equinor) conducted a feasibility study for CO2 storage at three different locations on the Norwegian continental shelf. Both Statoil and Gassnova considered a development solution for CO2 storage with a land plant and a pipeline to the Smeaheia area as the best solution given the objectives of the project. This was later changed.

Statoil (now Equinor), Shell, TotalEnergies and Gassnova, marked April 7, 2017 continuation of the Technology Center at Mongstad (TCM) until 2020. Gassnova, which manages the state’s ownership of TCM, negotiated with Statoil (now Equinor) and Shell about the continuation. They signed an agreement to continue the operation of TCM for another three years, and Total signed that they want to join the partnership.

Work on full-scale put on hold

Early 2017, Gassnova awarded study contracts to Fortum Oslo Varme (FOV) (now Hafslund Celsio), Heidelberg Materials and Yara. The companies received support for concept and pre-design studies for CO2 capture at their facilities, and the concept studies were completed as planned the same autumn. CO2 from one or more of these plants was planned to be transported by ship to an intermediate storage facility at Kollsnes and further transported by pipeline to a geological formation in the Smeaheia area in the North Sea.

Summer of 2017, Gassnova awarded a contract for concept and pre-design studies of CO2 storage to Statoil (now Equinor). Shortly thereafter, Statoil signed a partnership agreement with Shell and TotalEnergies on the development of the CO2 storage. The concept study for storage was scheduled to be completed in summer 2018.

The state budget for 2018, the government announced that work on full-scale CCS in Norway should be submitted to the Parliament after the results of the concept studies on capture were reviewed and quality assured, at the latest in connection with the revised national budget 2018. Thus, the catch projects were not directly carried forward to the pre-design phase accordring to the original plan.

In the first half of 2018, Gassnova worked closely with the Ministry of Energy to ensure a sound overall presentation to the Parliament on the work on full-scale CCS, in connection with the revision of the revised state budget.

At the end of 2018, it was decided to continue with the full-scale work. Both the capture projects at Fortum Oslo Varme (now Hafslund Celsio) and Heidelberg Materials were allowed to carry out pre-planning. In addition, Equinor, Shell and TotalEnergies would carry out pre-planning of the transport and storage project in 2019.

Resuming the work on fullscale CCS

When the Front-End Engineering studies are complete and external quality assurance has been completed, the government will consider whether the project should be realized. An investment decision can be made in 2020/2021. The government will then evaluate the results and information that comes from the preliminary planning, the potential for benefits realization and the economic manuvering space and submit the case to the Parliament. Work on benefits realization, knowledge sharing and communication has been central to Gassnova’s work. An important part of this work is to document that the Norwegian full-scale project can contribute to the realization of several new CO2 capture and storage projects in Europe.

On September 5, the Ministry of Energy, Gassnova and the European Commission gathered key policy makers from politics and industry to a high-level conference on CCS in Oslo. Among the participants in the conference were Norway’s Minster of Energy, the Minister of Climate and Environment and the Secretary General of the UN Climate Convention UNFCC, Patricia Espinosa. Several letters of intent were also signed between Equinor on behalf of the partners in the Northern Lights CO2 storage project and various European industrial companies. The recognition that CO2 capture and storage is one of several vital tools for climate neutrality in the EU in 2050 was a pervasive main message in addition to financing models for the climate measure.

Changes for CLIMIT

CLIMIT – Gassnova’s and the Research Council of Norway’s programme for research, development and demonstration of CO2 management technologies – has also undergone significant changes. From focusing primarily on CCS solutions for gas-fired power plants, the programme will now contribute to all possible CO2 sources. The three priorities of the programme are:

– Decarbonisation of industrial and energy resources

– Large-scale CO2 storage on the Norwegian continental shelf

– Development of innovative technologies and solutions for CCS.

The technology centre has found its place in the value chain

Today, Mongstad Technology Centre is the world’s largest and most flexible test centre for CO2 capture technology verification. And a leading centre of excellence in the field. Since its establishment in 2012, TCM has carried out 23 test campaigns of various capture technologies. TCM has played a key role in the development and commercialisation of technologies that enable CO2 capture and storage, both nationally and globally. The technology now used in the Longship project was first tested at TCM.

In spring 2020, the Norwegian government and industry partners TotalEnergies, Shell and Equinor agreed to continue operating the technology centre until the end of 2023. This agreement has now been extended to 2025. The share of each of the industrial owners has increased from 8.7 percent to 22.0 percent. The State’s share will be reduced from 73.9% to 34.0%.

Longship announcement adopted September 2020

Through the consideration of the State Budget for 2021 and the Longship report “Meld. St. 33 (2019–2020). Therefore the Norwegian Parliament agreed with the support model and the preconditions for further work.