Funding for Longship approved

Yesterday, the Norwegian Parliament adopted the budget for the Ministry of Energy for 2021, in line with what was proposed from the Government.

Longship

This includes funding for Longship, and the Ministry is given power of attorney to enter into agreements with Northern Lights, as proposed. The Storting also provided a few amendments, emphasising the need for cost control, risk management, and benefit realisation.

The Government has laid out its plans for Longship in a white paper, which will be debated by the Storting early in 2021. The formal approval of the plan for development/installation and operation (PDO/PIO) will take place as soon as the Storting has adopted the white paper.

Read more about the whole Longship project at ccsnorway.com

Report: Developing Longship – Key Lessons Learned

Gassnova has gathered its most important experiences from the six years planning of the CCS project «Longship» in a new report named «Developing Longship – Key Lessons Learned».

Called Longship

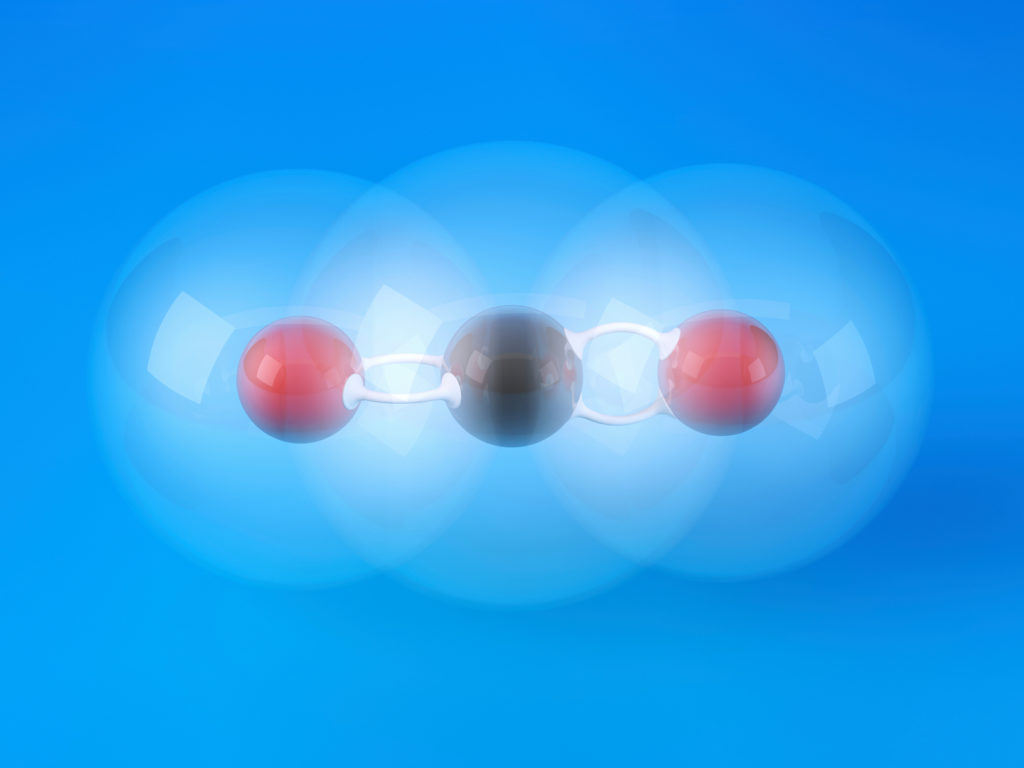

On 21 September, the Norwegian government presented a White Paper to the Parliament in which they recommended the realization of a project for the capture, transport and storage of CO2 in Norway – called “Longship”.

Gassnova a project integrator

The industry itself has been responsible for the planning of its sub-projects. Gassnova has been a project integrator, ensuring that the industry partners are well coordinated with each other and that the projects are developed in line with the state’s objectives.

«Longship» is a first-of-its-kind project when it comes to: the emission sources where the CO2 will be captured; the scalable transport and storage infrastructure ready to be used by other emission sources; and the application of European and Norwegian CCS regulations. The different technical solutions are in operation elsewhere but are put together for the first time to form a complete CCS chain.

“Developing Longship – Key Lessons Learned”, aimed at informing subsequent CCS projects, government actors and others who work to facilitate the use of CCS, draws out overall learning points and presents them in an easy-to-understand way.

For comprehensive information related to the project, there are a number of reports on ccsnorway.com. Feel free to contact Gassnova directly for further information, or to get in touch with the industry partners in Longship.

Gassnova is working to further the development of CCS technologies and knowledge related to CCS. A part of our mission as a state-owned innovation enterprise, is to share knowledge and experiences from the Longship project.

Heidelberg Materials has signed contracts with Aker Carbon Capture

Heidelberg Materials has signed a series of contracts with Aker Carbon Capture for delivery of the worlds first CCS plant at a cement factory.

Another step towards realizing the Brevik CCS plant

Aker Carbon Capture and Heidelberg Materials celebrated another milestone for the Brevik CCS project, as the companies formally signed a series of contracts for delivery of the worlds first carbon capture plant at a cement factory.

15 years’ work behind the Longship storage site

Gassnova, Equinor and the Norwegian Petroleum Directorate have for many years collaborated on the development of the subsea CO2 storage that the Longship project will use.

Longship “launched”

On September 21st this year, the Norwegian authorities “launched” the Norwegian CCS value chain project “Longship”, which includes capture, transport and storage of CO2.

The CO2 will be stored in the Johansen formation south of the Troll field, and behind the establishment of this storage is many years of work.

Norway has extensive experience with storage of CO2 in geological structures. Since 1996, CO2 have been captured each year from the hydrocarbon gas produced on the Sleipner West field in the North Sea.

The CO2 storage in the Johansen formation in exploitation permit 001 (EL001) will be the third subsea CO2 storage developed in Norway.

Several years to mature a possible CO2 storage

It can take several years to mature a possible CO2 storage until it is ready to receive an injection of CO2. The timeline presented in the article below shows all the measures taken prior to the decision to submit a plan for development and operation (PDO) for transport – and the storage part of the project – with the name Northern Lights.

The process of finding a possible CO2 storage facility for the Longship project began with a review of the Norwegian continental shelf in 2007. This was then matured through several stages, and will continue in the future as more CO2 storage facilities are expected to be developed.

Read the whole story, including the most important steps in the process of finding a possible CO2 storage, described in chronological order.

Studies focusing on amine components

Studies of amines, nitrosamines and nitramines and how they can occur in amine-based CO2 capture were initiated in Norway as early as 2007. Here we have collected reports from the work that has been financed through the various parts of Gassnova.

Since it became evident that amines could undergo photochemical reactions with free radicals and NOx in the atmosphere to form nitrosamines and nitramines, emissions of amines have been high on the agenda for Norwegian environmental authorities. Some nitrosamines and nitramines have shown carcinogenic effects in animal studies, thus spreading in the environment is not acceptable and should be limited.

Studies on these compounds and how they are linked to amine-based CO2-capture were initiated as early as in 2007 and results of this work co-funded through the different parts of Gassnova ca be found in the linked documentation below.

CLIMIT fundes studies

CLIMIT cofunded the first set of studies from 2008. These studies started up as literature surveys (NILU phase 1) to map available knowledge on the subject and developed further to test properties of amines with respect to formation of nitrosamines and nitramines under capture and atmospheric conditions as well as toxicity and degradation of nitrosamines and nitramines in the environment. The two reports which summarize this comprehensive work best are:

Amine emissions to air during carbon capture. Phase I: CO2 and amines screening study for effects to the environment.

Atmospheric Degradation of Amines (ADA): Summary report from atmospheric chemistry studies of amines, nitrosamines, nitramines and amides.

TCM fundes studies

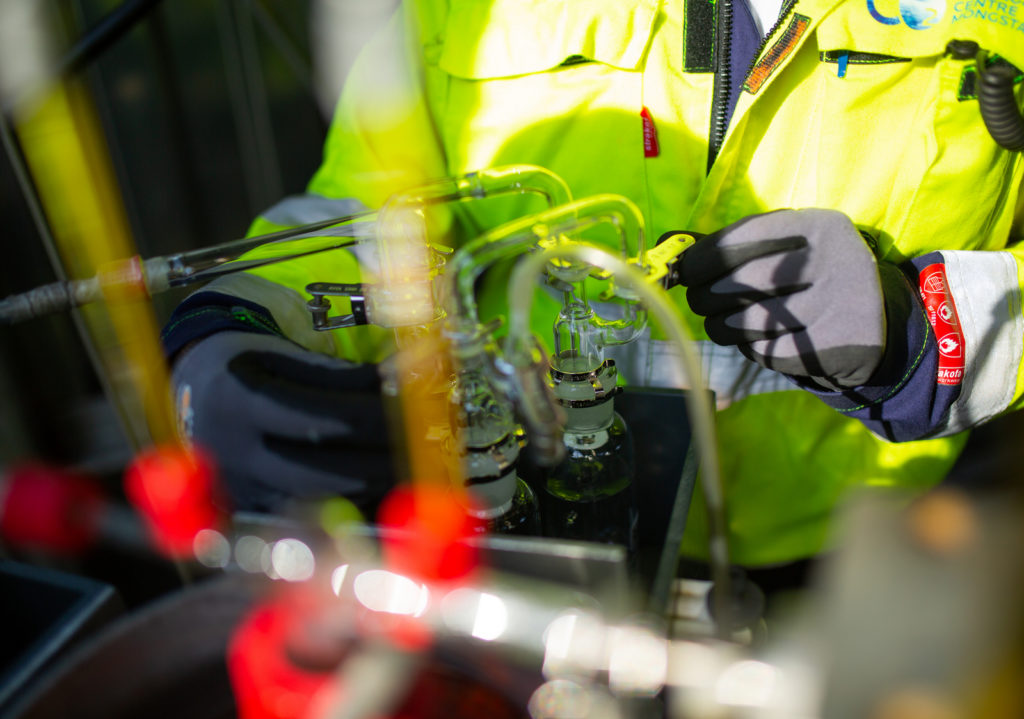

Technology Centre Mongstad (TCM) were supposed to start up its test activities around 2010, a.o. amine-based CO2 capture. A discharge permit was required for both amines, nitrosamines and nitramines. Thus, the urgent work was to acquire enough information and background to get such a permit from the authorities.

Several studies were conducted to improve the understanding of the atmospheric chemistry of amines as well as the environmental faith and pathways of Nitramines and Nitrosamines. Reports from these studies are found here at TCM’s homepage.

Full-scale Mongstad (CCM) fundes studies

The full-scale Mongstad project (CCM) started up in 2009. Technologies were supposed to be qualified for CO2 capture at the CCGT plant at Mongstad and amine technology was the most mature solution.

A comprehensive work was initiated to establish a technology qualification program with the aim of documenting amine capture being a safe solution for CO2 capture. The project was terminated in 2013 but the most important results of this project – a set of more than 60 reports concerning amines, nitrosamine and nitramines – are listed on ccsnorway.com.

Publications: Based on all work carried out within this field and funded by all three branches of Gassnova several papers have been published. Here shown with two summary papers:

Gjernes, E., L.I. Helgesen, Y. Maree: «Health and Environmental impact of amine based post combustion CO2 capture”, Energy Procedia, Volume 37, 2013, page 735-742

Helgesen, L.I. and E. Gjernes: «A way of qualifying Amine Based Capture Technologies with respect to Health and Environmental Properties”, Energy Procedia, Volume 86, January 2016, page 239-251

Ready to realize full chain carbon capture and storage

In a Government White Paper to the Norwegian parliament submitted today, the Government proposes to launch a carbon capture and storage (CCS) project in Norway.

The government’s recommendation

– We are very pleased with the government’s recommendation. The government proposes to first realize the capture of CO2 (CCS) at Heidelberg Materials’s cement factory in Brevik. The Government also plans to support the capture of CO2 at Fortum Oslo Varme’s waste management facility in Oslo, provided that this project first obtains sufficient self-financing and financing from the EU or other sources.

The Government’s decision is based on extensive work carried out by Gassnova and the industrial partners we have collaborated with over the past five years. The decision is also inspiring for all our skilled and committed employees, who have worked to help us now realize full-scale CCS in Norway, says Trude Sundset, Gassnovas CEO.

Here you can read more about Gassnova’s reports and recommendations

Press release from the Norwegian Ministry of Energy

The Norwegian CCS project is featured on German TV

A ZDF documentary about the Norwegian carbon capture and storage project (CCS), is now available for online viewing.

Germany’s largest TV channel (ZDF)

The 30-minute documentary about the Norwegian full-scale project, produced by Germany’s largest TV channel (ZDF), was broadcasted on their sister channel 3Sat on Tuesday 25 August, and will be broadcasted several times in the weeks ahead on both ZDF, ARD, ORF and SRF.

The documentary includes interviews with Trude Sundset, Gassnova’s CEO; Sverre Overå, Equinor’s project director for the transport and storage part of the project; and Jannicke Bjerkås, project director for Fortum Oslo Varme’s CCS project.

Read here how 3Sat advertises the documentary

Here is more information about the Norwegian CCS project: ccsnorway.com

Three more years of testing at Technology Centre Mongstad

The Norwegian state and the industry partners Total, Shell and Equinor have signed the agreements that ensure continued operation of Technology Centre Mongstad (TCM) from now until the end of 2023.

Increasing interest for testing

“We see an increasing interest for testing at TCM, and we are very pleased that we can continue our important work with testing and research necessary for the deployment of large-scale carbon capture. In addition to the amine plant and chilled ammonia plant, TCM also offers testing in smaller modular scale at our new third site. We also see an increasing interest for our advisory services, and this will play an important role also in the years to come”, says TCM Chairman Roy Vardheim of Gassnova.

TCM is owned by the Norwegian State, through Gassnova (73.9%), together with the industry partners Equinor (8.7%), Shell (8.7%) and Total (8.7%).

“To succeed with the energy transition, we need close collaboration between the industry and supplier. Developing and testing technologies that bring down costs and risks in CCS value streams is key. TCM has contributed to maturing the carbon capture supplier market and will remain relevant with the increasing number of technology suppliers lining up for testing. In Equinor we have an ambition to build hydrogen value chains, and safe and efficient CCS technologies will be important to succeed, “ says Irene Rummelhoff, Executive Vice President of Marketing, Midstream & Processing in Equinor.

“We are pleased to continue to work with TCM and our partners for the coming three years to strengthen TCM’s position as a leading centre for carbon capture expertise that is recognized for the high-quality services it provides. TCM plays a key role in further developing and reducing the cost of CCS – a crucial technology to help society and economies thrive through the energy transition,” says Christiaan van der Eijk, CCS Manager in Norske Shell and TCM board member.

“TCM is a cornerstone in Total’s strategy to tackle climate change by accelerating the development and adoption of innovative CO2 capture technologies,” says Jeremy Cutler, R&D Manager in Total E&P Norge AS and TCM Board Member.

An important part of the Norwegian carbon capture and storage (CCS) efforts

When the Norwegian government in March this year announced their intent to continue their ownership in TCM for the coming years, the Norwegian Minster of Energy, Tina Bru said: “The Technology Centre at Mongstad is an important part of the Norwegian carbon capture and storage (CCS) efforts, making significant contributions to the development of a necessary tool to mitigate climate change. I appreciate that we have reached an agreement with the partners Equinor, Shell and Total to continue the operation of the facilities. The industrial commitment to TCM is very important for the government. The new agreement provides a good foundation to continue the positive development at TCM”.

Read the full press release from the Norwegian Ministry of Energy regarding the decision of continuing operation at TCM here.

About TCM

TCM, located next to Equinor’s refinery on the west coast of Norway, has a unique scale and flexibility in terms of ability to simulate real-world conditions for post-combustion capture, and ability to test a multitude of different mature and emerging technologies in a cost-effective manner. Large-scale and real-world testing fills an important gap between small-scale piloting and full-scale deployment, and a number of key CCS companies have qualified their technologies at TCM since its inauguration in 2012.

Read more about TCM at www.tcmda.com

ESA approves financing of the Norwegian full-scale CCS project

-This CCS project is a groundbreaking step towards tackling climate change – an issue that affects all of us, said Bente Angell-Hansen, President of ESA, in a press relase about the approval.

Up to €2.1bn in aid to meet climate goals

The CCS Full-Scale project is a central part of Norway’s efforts to reduce its carbon footprint and meet the European goal of climate-neutrality by 2050. It is the largest single state aid award ever approved by the EFTA Surveillance Authority (ESA).

Carbon Capture and Storage (CCS) has been recognised by the European Union as key to reducing the harmful environmental effects of carbon-intensive sectors (such as construction), where emissions are difficult to avoid.

Read the press release from the EFTA Surveillance Authority ESA here

Milestone for Swedish-Norwegian CCS project

Today, Sweden’s largest CO2 capture test plant starts at Preem’s refinery in Lysekil, with support from CLIMIT and Swedish energy authorities. The goal is for the tests to form the basis for a full-scale CCS plant and send CO2 for storage in Norway.

Swedish-Norwegian cooperation

– It is very positive that Sweden and Norway can collaborate and develop a pioneering, international infrastructure for CCS in Europe, says Trude Sundset, CEO of Gassnova.

The pilot project in Lysekil is a collaboration between Preem, Aker Solutions, Chalmers University of Technology, Equinor and the Norwegian research institute SINTEF. The Swedish Energy Agency and the Norwegian research and technology development program CLIMIT contribute with funding.

The entire value chain will be evaluated

From carbon capture at the refinery, local storage, transport to the planned storage location off the Norwegian west coast and for the storage itself. The results of the pilot project will then be made public – in order for more companies to be able to use the technology and reduce their carbon dioxide emissions. This knowledge sharing is in line with the thinking in the Norwegian full-scale project.

The mobile test facility (MTU) from Aker Solutions, which starts at Lysekil today, has previously run test campaigns at several locations in Norway, including at the Technology Center Mongstad (TCM) and Heidelberg Materials’s cement plant in Brevik. In 2020, the test facility will capture carbon dioxide from the flue gases from Preem’s hydrogen gas plant at the Lysekil refinery.

Climate neutral by the year 2045

The technology for capturing and storing carbon dioxide is an important component for reducing greenhouse gas emissions and for achieving Sweden’s and Norway’s climate goals. For Preem, this is an important piece of the puzzle to reduce carbon dioxide emissions and to become climate neutral by the year 2045. The goal is for the tests to form the basis for a full-scale CCS plant that can be operational by 2025.

– We see carbon capture and storage as a vital measure to reduce global carbon emissions. For Preem, a full-scale CCS plant could initially reduce emissions from our Lysekil refinery by 500,000 tonnes, which is close to a quarter of the refinery’s total carbon emissions, says Petter Holland, CEO of Preem.

The full-scale project in Norway, which includes a transport and storage project led by Equinor, is scheduled for a final investment decision in the Norwegian Parliament this fall, and – if all goes according to plan – can be put into operation three years after.

Last Fall, Preem signed a Memorandum of Understanding with the Northern Lights consortium regarding sending the CO2 to their planned CO2 storage

– Equinor is involved in several different projects in the capture, transport and storage of carbon dioxide. This project can give us third-party volume for our transport and storage project, Northern Lights. In addition, a carbon capture technology is used that may be relevant for our facilities. This type of collaboration between industry, research and government is crucial to the success of carbon capture and storage, says Torbjørg Klara Fossum, Vice President of Global CCS Solutions at Equinor.

Since 2014, Gassnova has worked closely with industry to put in place what could be Europe’s first industrial CCS project. Initially, it is planned that CO2 will be captured from Heidelberg Materials’s cement plant in Brevik and/or from Fortum’s Oslo waste-to-energy plant in Oslo. Subsequently, the CO2 will be transported by ship to a land facility outside Bergen before it will be piped to a storage deep below the seabed in the North Sea.

For more information

CLIMIT and the Norwegian full-scale project

For more on Preem’s CCS initiative: https://www.preem.se/om-preem/hallbarhet/ccs/

For more info on Northern Lights: https://norlights.com/