16.06.2021

German interest in Norwegian CCS work

In the German political debate there has been an increasing focus on CCS to achieve tighter climate goals by 2050. Now German politicians will learn more about the Norwegian model for CCS, and what Norway is about to offer Europe.

Falling costs

Equinor invited Gassnova to present experiences from the Langskip project to the German ambassador to Norway, Equinor’s country manager in Germany, the Norwegian Petroleum Directorate and German politicians. The societal goal for Langskip is that a demonstration of CO2 management will provide the necessary development of CCS beyond Norway’s borders. CCS will contribute to achieving the long-term climate goals in Norway and the EU at the lowest possible cost. The head of the CCS technology and knowledge hub department in Gassnova, Audun Røsjorde, spoke about the experiences from the development and testing of technology, including the cost picture for CCS in the future. Experience from other industries and technologies shows that costs will fall over time due to upscaling and innovation.

Innovation and learning important to reduce costs

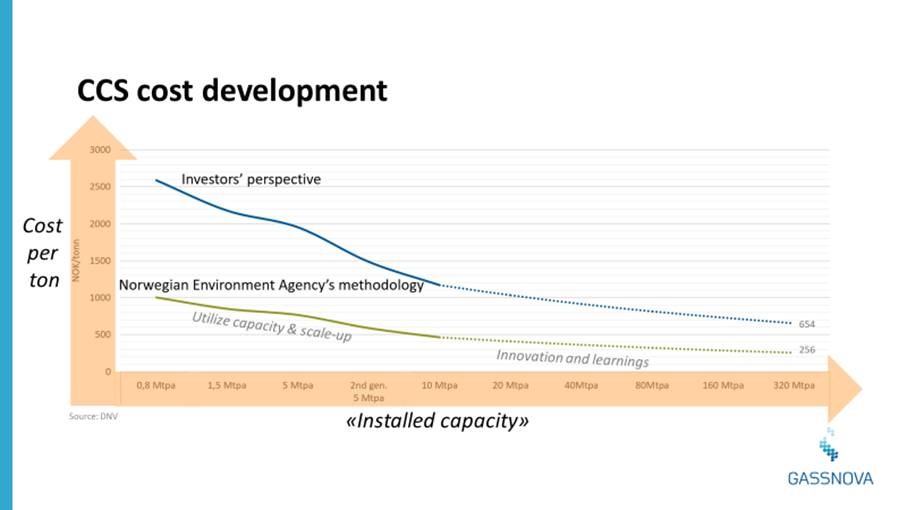

There are different ways to calculate the cost of CCS, and the figure shows two cost curves based on different assumptions. The main difference between the two curves is the expectation of return: An investor has a higher expectation than society. One axis shows cost per tonne, while the other shows ‘installed capacity’ (total capacity in the world). The figures are based on the ‘Longship’ project, and the starting point for the baskets is the cost per tonne for the Longship CCS chain from day one.

Since the receiving terminal handles more CO2 than Heidelberg Materials and possibly Fortum can capture and deliver, the first step will be to utilise the extra capacity. This will reduce costs per tonne. Similarly, the pipeline also has a higher capacity than the rest of the value chain, and an expansion with, among other things, more ships and wells will further reduce the cost per tonne. The costs per tonne will fall more if larger capture facilities are included in the value chain. In the initial phase, the cost per tonne will therefore decrease due to better capacity utilisation and upscaling. To bring costs down further, innovation and learning will play a more important role (shown by the dotted sections of the curves). See the report that discusses this cost development curve here. The report was prepared in connection with the socio-economic analysis (Appendix 4).

CCS in Germany

In April, the German industry association BDI published a discussion note indicating that CCUS must now be considered for industries that are difficult to decarbonise, as well as for the production of hydrogen from natural gas. Also, among various think tanks and NGOs in Germany, which have traditionally expressed skepticism about the use of CCS, there are now reports of changed assessments. Among other things, Agora Energiewende published a report in May in which they present an analysis that indicates that CCS may have to be used in Germany as early as 2030 to achieve ambitious climate goals.

You will find more detail about CCS in Germany in our environmental analysis.

Edit this text area as you want, make headings and paragraphs…